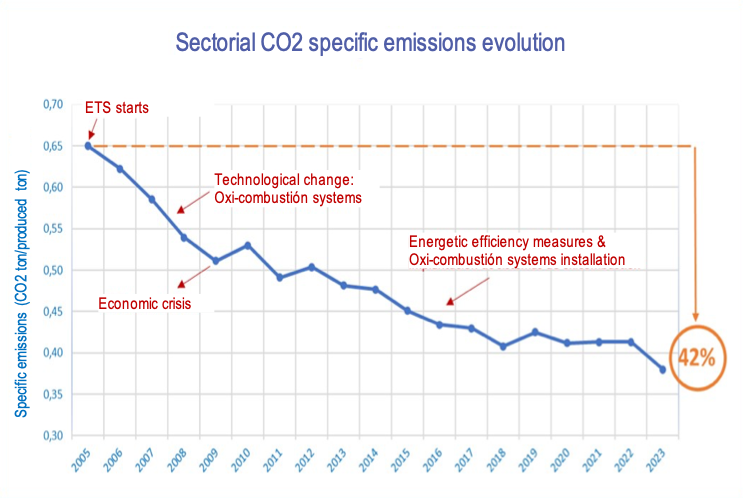

The industry has been committed to the environment and reducing emissions for years, which is reflected in the optimisation of its production processes, such as a commitment to oxy-combustion systems, which have enabled a reduction of more than 40% in CO2 emissions since 2005, when the emissions trading scheme (ETS) was introduced.

Innovation and sustainable development

The industry has been a world leader in R&D&I, design, quality, sales, and customer service for decades, and its prestige is recognised worldwide.

Its commitment to sustainability is reflected in the innovation applied to both its production processes and its products. Since 2005, innovative technological changes have been adopted in its production processes, such as installing oxy-combustion systems and energy efficiency measures to reduce its carbon footprint. Furthermore, the need to make the production of its products compatible with environmental protection has led to the minimisation or elimination of the use of certain raw materials, or the search for substitute raw materials in order to make the product increasingly sustainable.

However, the particularities of the production process mean that, in the case of frits, the components are inerted in the production process itself. Furthermore, the industry makes efficient use of water, having installed closed-circuit cooling systems and treatment plants.

Products are released onto the market with the highest quality and health guarantees, and with the relevant instructions for the correct use by the client. In fact, after-sales service to clients is one of the hallmarks of this industry. It not only sells the product, but also, thanks to its technical-commercial service, it ensures that said product is used correctly by the client company by monitoring its implementation and resolving any technical complications that may arise in order to guarantee the final result and the desired finish on the ceramic tile, or other applications.

Carbon footprint reduction

The industry has been working hard for years to reduce its carbon footprint and cut CO2 emissions.

Since the EU Emissions Trading System (ETS) came into force to combat global warming, the industry has committed to technological change by installing oxy-combustion systems and energy efficiency measures, which have led to a reduction of more than 40% in the emission ratio (tonnes of CO2 per tonne produced) since 2005.

Decarbonisation of the sector

The industry, which is energy intensive (especially natural gas, which accounts for more than 90% of the energy bill), faces the biggest decarbonisation challenge posed by the European Union, consisting of net zero greenhouse gas emissions by 2050.

Current technologies are mature, and therefore offer little scope for improvement in terms of achieving significant emissions reductions, which means that the industry needs disruptive technologies to meet its emission reduction targets.

In its commitment to decarbonisation and advancing its sustainable commitment, innovative nature, and global leadership, ANFFECC is leading the H2frit project, which proposes an energy and technological change by replacing natural gas with hydrogen for fusing its ceramic frits.

In addition, the technical and economic development of other technologies (electrification, CO2 capture, renewable gases, etc.) will be key to achieving the reduction targets while ensuring the industry's long-term sustainability and competitiveness.

Eco-label:

Environmental Product Declaration

Product Carbon Footprint

In 2024, ANFFECC developed sectoral EPDs and PCFs for its products: frits, grit, glazes (dry-based, liquid, and micronised), inorganic pigments, and digital injection inks.

Sectoral Environmental Product Declarations (EPDs) (type III eco-labels) provide objective, quantified and verifiable information on the environmental profile of products throughout their life cycle.

On the other hand, sectoral Product Carbon Footprints (PCFs) reflect all greenhouse gases potentially emitted as a direct or indirect result of a product throughout its life cycle, expressed in kg of CO2 equivalent.

Sectoral EPDs (Environmental Product Declarations) and PCFs (Climate Declarations) have been registered with the Environdec® system (The International EPD System), and published in the EPD library (https://www.environdec.com/library), with registration numbers: EPD-IES-0015440:001, EPD-IES-0015441:001, EPD-IES-001544El3:001, EPD-IES-0015444:001, EPD-IES-0015445:001, EPD-IES-0015446:001, and EPD-IES-0015447:001.

Best Available Techniques (BATs)

The first Best Available Techniques Reference Documents (BREFs) were adopted under the IPPC Directive to reflect Best Available Techniques (BAT), and are revised and adapted to the legal framework of the Industrial Emissions Directive (IED). As such, the BREF documents are mandatory reference documents.

ANFFECC, representing the industry, together with the Ceramic Technology Institute, ITC-AICE, actively participates in the working groups for the preparation and review of the BREFs for glass and WGC BREF (BREF on waste gas treatment in the chemical sector).

BREFs are usually sector-specific and generally provide information on an industrial sector, the techniques and processes used in that sector, current emission and consumption levels, techniques to be considered for determining BATs, and emerging techniques.

The conclusions of the BATs are the reference for setting emission limits for Integrated Environmental Authorisations (IEAs).

Pollution prevention, reduction, and control

Industries in the sector have various measures in place to prevent, reduce, and control pollution:

Reduction of emissions of particulates, NOx, CO2, and SO2 into the atmosphere from localised sources through numerous means, including:

- Oxy-fuel combustion

- Reformulation of compositions

- Improving energy efficiency

- Renovation or installation of gas stream de-dusting systems.

- Installation of atmospheric emission purification systems.

Reduction of particle emissions into the atmosphere from material storage, handling, and transport transactions through the:

- Enclosure of facilities.

- Aspiration and dust removal from facilities.

- Conditioning, paving, and cleaning.

Reducing the impact of packaging by adapting to new national regulations and introducing current sectoral Deposit, Return, and Refund Systems (SDDR) within a collective EPR (Extended Producer Responsibility) system.

Noise reduction through the enclosure and insulation of noise-emitting facilities.

Efficient use of water through the installation of closed-circuit cooling systems and treatment plants.

Reduction, recycling, and management of waste generated through selective collection, separation, and temporary storage systems.

Reduction of visual impact by adapting the facility and its surroundings to improve landscape integration.