What are frits?

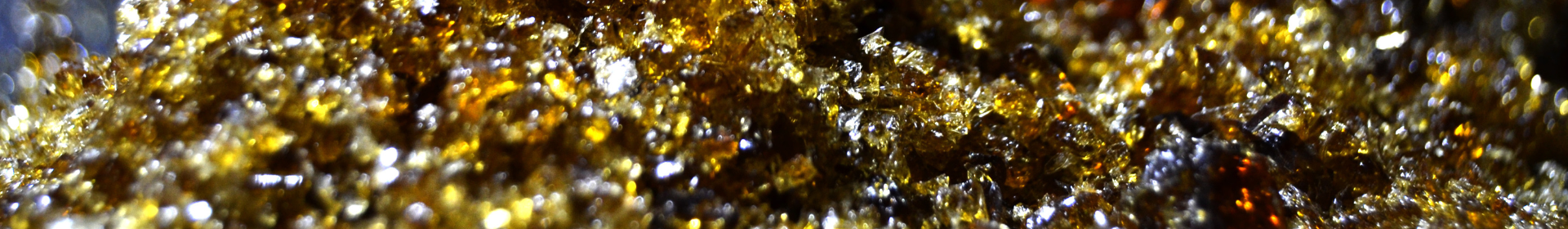

Frits are inorganic, glassy substances, practically insoluble in water, that are obtained by melting a mixture of raw materials at high temperatures (between 1200 and 1500 ºC). These raw materials can be of natural or synthetic origin, such as oxides, silicates, carbonates, aluminosilicates, borates, etc. The molten mass is rapidly cooled with air or water, resulting in a glassy mass called "frit". As a result, the new glass structure formed has different properties from those of the initial materials..

From the point of view of industrial processes for manufacturing ceramic floor and wall tiles, frits are processed raw materials used to prepare engobes, glazes, and inks, providing a series of properties that improve the appearance and functionality of ceramic tiles.

Frits have a wide range of uses and applications, from ceramics (the most common) to more specific uses in industries such as flat and/or hollow glass manufacturing, photovoltaics, medicine, electronics, construction, automotive, galvanising/enamelling of metal surfaces, and traditional and artistic ceramics.

How are they produced?

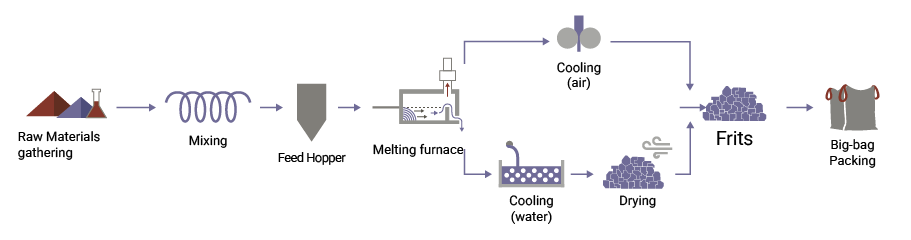

The production process of a frit aims to obtain a vitreous product, practically insoluble in water, which is obtained by the melting and subsequent cooling of homogeneous mixtures of different crystalline raw materials.

The frit production process involves different stages, from the reception and storage of raw materials (closed silos), their dosing and mixing (dry or wet), transport and loading into the melting kilns (usually automated), cooling of the viscous fluid at the kiln's outlet (usually with water, although cooled rollers can also be used), and storage of the final frit.

The ceramic frit industry mainly uses continuous melting kilns, although discontinuous kilns can also be used. The choice of kiln type depends mainly on the scale of production and type of formulation.

Production remains constant (production capacity 20-40 tonnes/day) due to the continuous feeding of raw materials into the kiln.

Frit kilns use natural gas as fuel, and natural air, oxygen-enriched air, or pure oxygen as a combustion agent, with melting temperatures ranging from 1200 °C to 1500 °C. They generally operate under slightly negative pressure to ensure an oxidising atmosphere and the flow of the molten mass.

Once they have passed the various quality controls, the frits are ready for storage and subsequent use.

Hot and cold channelised emissions are generated during the production process, as well as scrap from the process itself, which in turn becomes part of the production process again. Similarly, the water used to cool the frits is reused in the production process, as it forms part of a closed circuit.