What are glazes?

Glazes generally include in their formulation a mixture of frits, inorganic pigments, raw materials, semi-finished products, and additives. They are usually prepared in the form of an aqueous suspension, which is applied to the substrate (part of the tile consisting of the clay-like material). Subsequently, it is subjected to a firing process that results in a ceramic tile with the desired final properties, providing aesthetic and decorative elements to the surface on which it has been applied.

Glazes have a wide variety of uses and applications. Ceramic uses/applications predominate, but they also provide added value in sectors such as construction, automotive, glass decoration, and metal surfaces.

There are three types of glazes: dry-based glazes, liquid-based glazes, and micronised glazes.

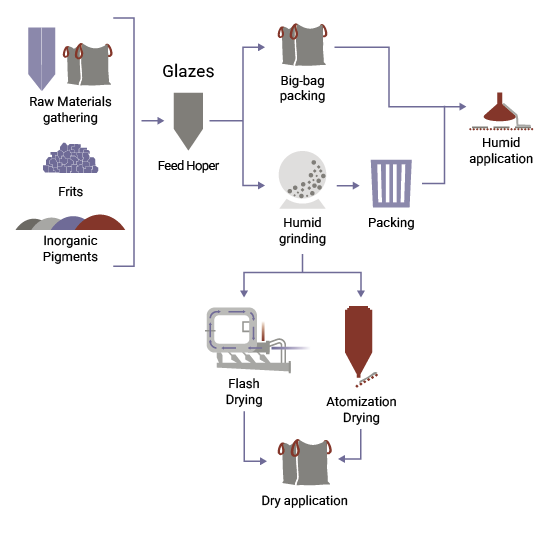

How are they produced?

In the preparation of dry-based glazes, the important parts are the stages of dosing and mixing the different constituents for subsequent packaging and storage.

Liquid-based glazes are the result of wet grinding the different constituents. They are commonly known as slips. The liquid-solid ratio will be determined, among other factors, by the type of application for which the glaze is intended. Grinding is generally carried out using high-density alumina balls as machining elements, and the grinding time will depend on the desired particle size properties, as well as on the rheology of the slip obtained.

Micronised glazes are obtained from liquid-based glazes that go through an energetic drying process (usually turbo-dryers, but optionally spray-dryers can also be used), thereby obtaining a material with a very small particle size (D50 < 45 µm).