What are inorganic pigments?

Inorganic pigments are chemical substances manufactured by an industrial process involving a chemical reaction in a solid state. In this process, a mixture of raw materials (metal oxides and salts) undergoes a calcination reaction at high temperatures, forming a specific and stable crystalline matrix.

In general, inorganic pigments have poor solubility and very low reactivity. These substances are used in high-temperature applications due to their extreme durability, which offers lightfastness and weather stability.

Pigments are normally presented in powder form and are marketed with a defined grain size distribution depending on the decorative effects to be achieved.

The uses and applications for inorganic pigments cover a wide range, from ceramics (the most common) to more specialised uses in industries such as flat and/or hollow glass decoration, tableware, construction, automotive, plastics, galvanising/enamelling of metal surfaces, and traditional and artistic ceramics.

How are they produced?

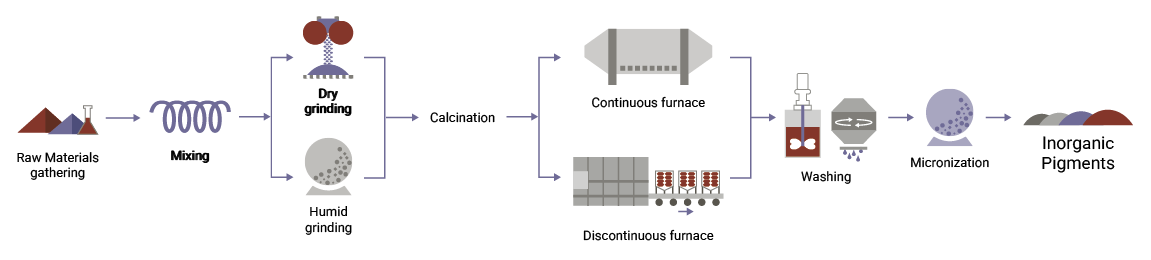

The production of inorganic pigments is a complex process that requires careful control at all stages, ranging from receiving and storing raw materials, dosing and mixing them (dry or wet), transporting and loading them into the calcination kilns (usually automated), and unloading of the calcined pigment for subsequent grinding, packaging, and storage until their final use or distribution.

The raw materials are mixed in specific proportions, which must be precise to ensure colour consistency. In some cases, the mixture may be atomised or granulated, adding binding agents or fixatives to create agglomerates or granules that facilitate the processing and dispersion of the pigment in ceramic glazes.

The calcination process (high temperature) results in a new substance with a crystalline structure and physical and chemical properties that are completely different from those of the starting materials. The temperature and calcination time vary depending on the type of pigment. After calcination, the pigments are ground again and, optionally, dried and micronised to obtain a fine, homogeneous powder. This additional grinding stage is crucial to achieving uniform dispersion of the pigment in ceramic glazes.