What are digital inkjet inks?

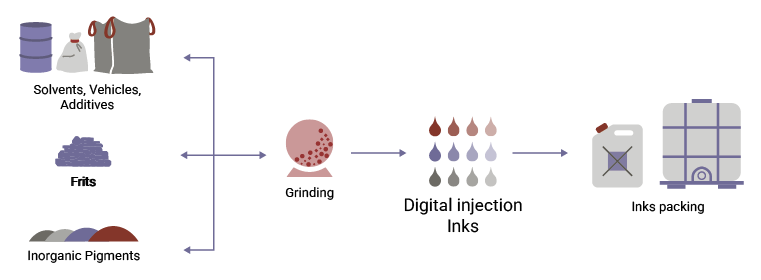

Digital inkjet ink is generally defined as a suspension composed mainly of a liquid part (solvent mixture), a solid part (pigment or inorganic material), and a dispersing component.

In firing decoration processes, inkjet inks undergo a chemical transformation in which the solvent mixture burns away, leaving the pigment permanently fixed on the surface to which it is applied. This process gives the ink remarkable resistance to high temperatures and long-term durability.

The uses and applications for digital inkjet inks are wide-ranging, from ceramics (the most common) to more specialised applications in industries such as flat and/or hollow glass decoration, textiles, tableware, automotive, construction, paper, wood, galvanising/enamelling of metal surfaces, and traditional and artistic ceramics.

How are they produced?

Digital inkjet inks for the ceramic industry represent one of the most important innovations in this industrial sector.

They are specifically formulated for applying with digital ceramic printers. Unlike traditional methods, they are printed directly onto the ceramic through an inkjet printing process (dispersed through thermal or piezoelectric injectors), allowing for high-resolution images to be reproduced.

Pigments are usually the main component that makes up the solid part of the ink, and their primary function is to give the ink the desired properties such as colour, opacity, and thermal stability. The dispersing component has the function of keeping the distribution of solid particles as homogeneous as possible within the suspension, ensuring excellent adhesion of the ink to the ceramic surface during the firing process. Solvents are used to dilute the ink, make it easier to apply, and aid in drying.